GRP - Glass Reinforced Plastic

FiberFlo is a brand focused on resilient composite pipeline systems, manufactured by Atagor. It finds use in power engineering as well as in many other industries. GRP – Glass Reinforced Plastic (also GFK – Glasfaserverkstärkten Kunststoffen) is a compound material characterised by complete corrosion resistance and robust mechanical strength.

In manufacturing process we use the most modern CNC winders, that allow us to use glass fiber threads, ensuring excellent durability and low weight of the final product. Our goal is to provide technical support alongside the whole investment or repair process, and to come up with the most effective solutions, suited to particular needs of our clients.

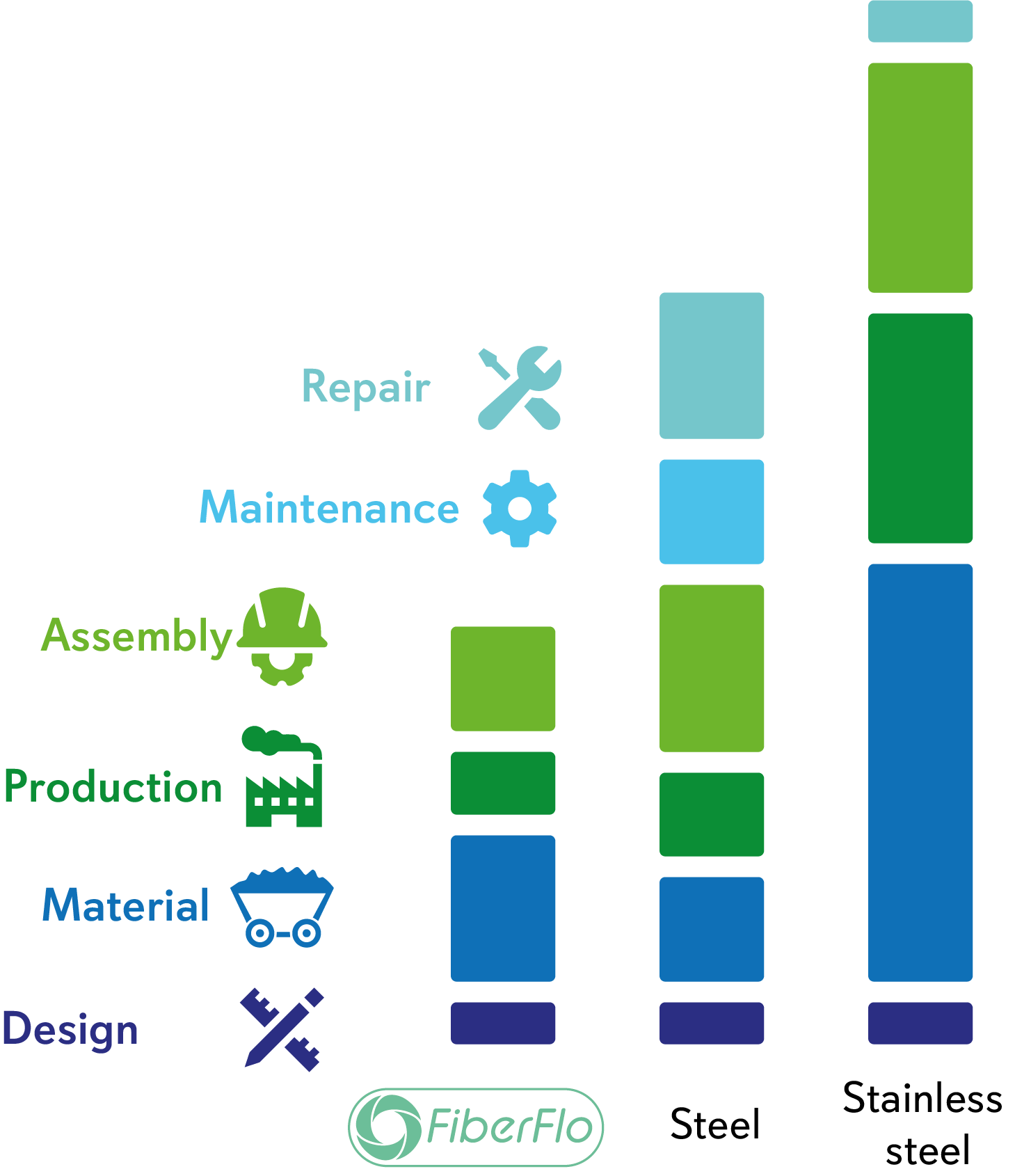

Chart comparing material costs and inputs at each stage of the project

Benefits of GRP systems

high resistance to abrasion

smooth inner surface

- low pumping costs

low weight

(more than four times less than steel) - low installation costs

low coefficient of linear thermal expansion

self-compensation at cross-winding up to 0.2%

resistant to high and low temperatures

(up to 150°C)

chemical resistance

to most gases and liquids, corrosion resistance

long service life

- 20 to 50 years

maintenance-free

(fix & forget)

Products

Pipelines

- diameter range: DN 25 up to DN 2000

- roving woven constructional layer

- pressure range PN4-PN40

- operating temperature up to 150⁰C

- wide range of connections: flanged, laminated, glued, socket welding

- type D pipes in accordance with norm DIN 16965-4

- type E pipes in accordance with norm DIN 16965-5

thermal insulation, leak monitoring

Tanks

- diameter range: DN 600 up to DN 4000

- length 500 – 12000mm

- pressurised and no pressure containters up to PN16

- vertical and horizontal oriented containers

- double jacket containers for storing hazardous materials

- spigots and connections according to project

Special products & apparatuses

- lamella apparatuses

- filters, rinsers

- absorbers, scrubbers

- pressure and pressureless apparatuses ( based on the project)

- atypical diameters, bends and fittings

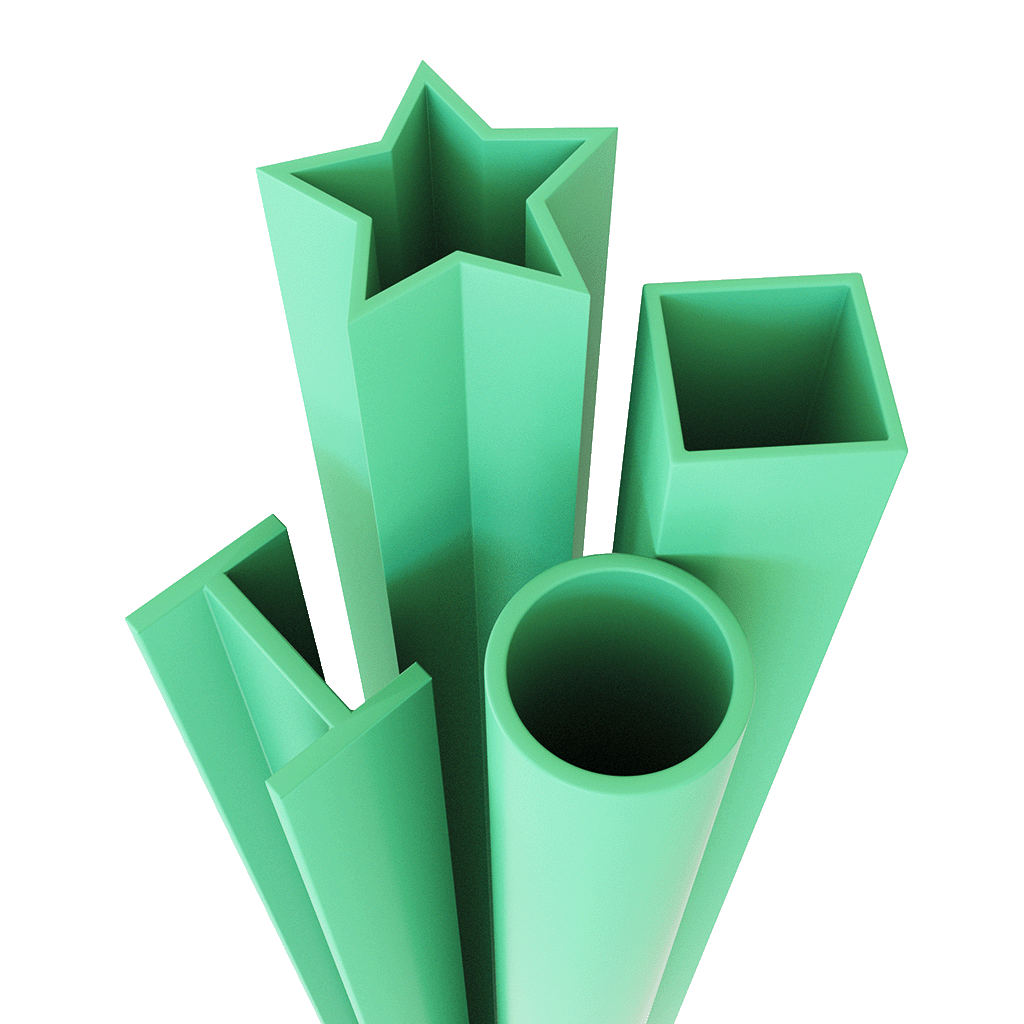

Pultruded profiles

- we can make any transversal profile (max. size 1000mm x 260mm) in cooperation with a client

- T-profiles, C- profiles, double-T profiles

- try brackets, rods

- daises, covers

- floor plates

- profiles for electronics

FiberFlo allows production from a variety of fibres, adapting to specific project requirements, whether you need the strength of carbon, natural flexibility of basalt or classic durability of glass.

Our technology minimises environmental impact while offering exceptional technical performance.

GRP in various industries

Heating & geothermal industry

Ship-building

Electroplating

Waste incineration plants

Chemical industry

Water pumping stations

Cellulose and paper industry

Sewage treatment plants

Mining

Our projects

Process plant for water/oil separator, PN10, DN200, 2018-2019

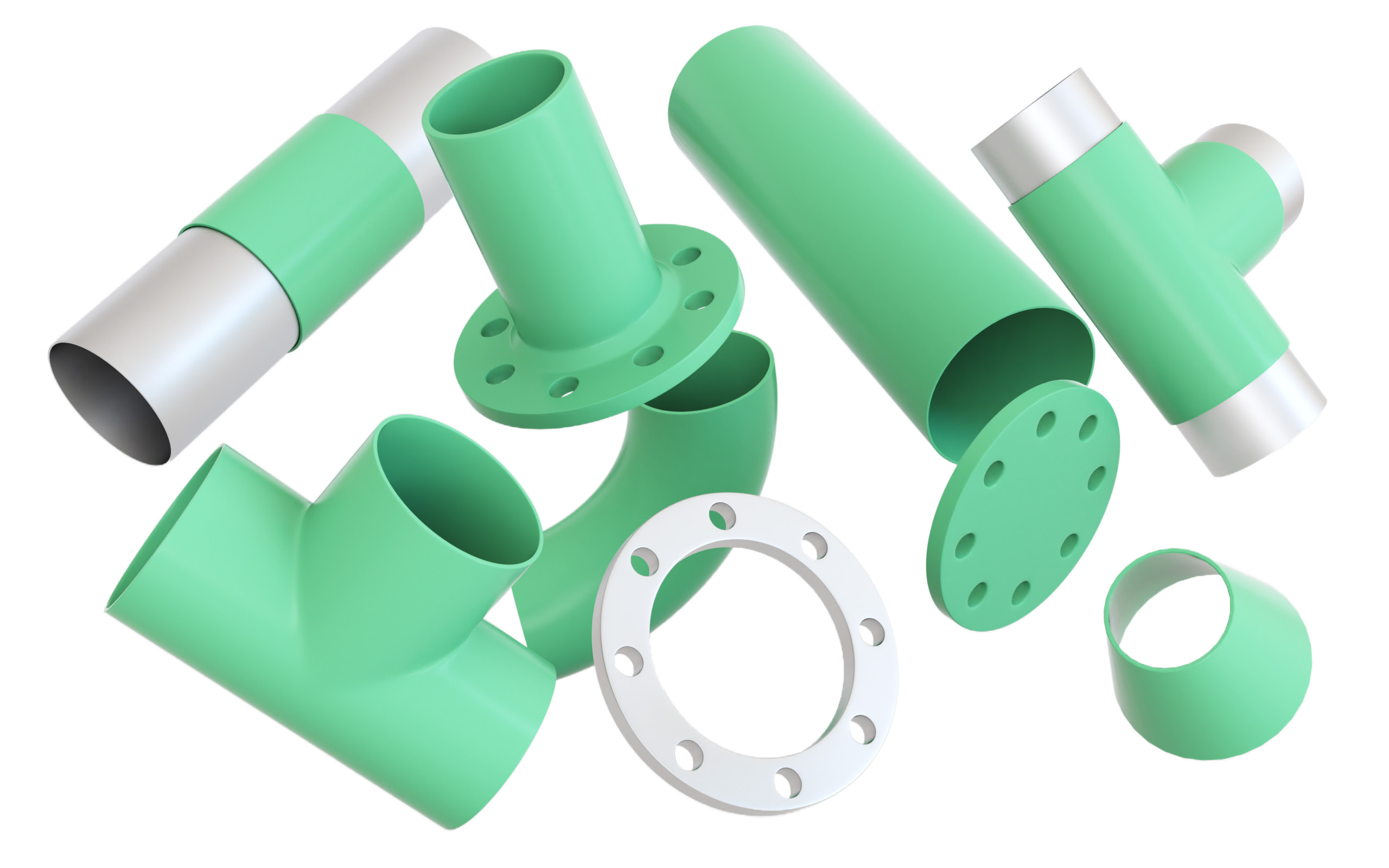

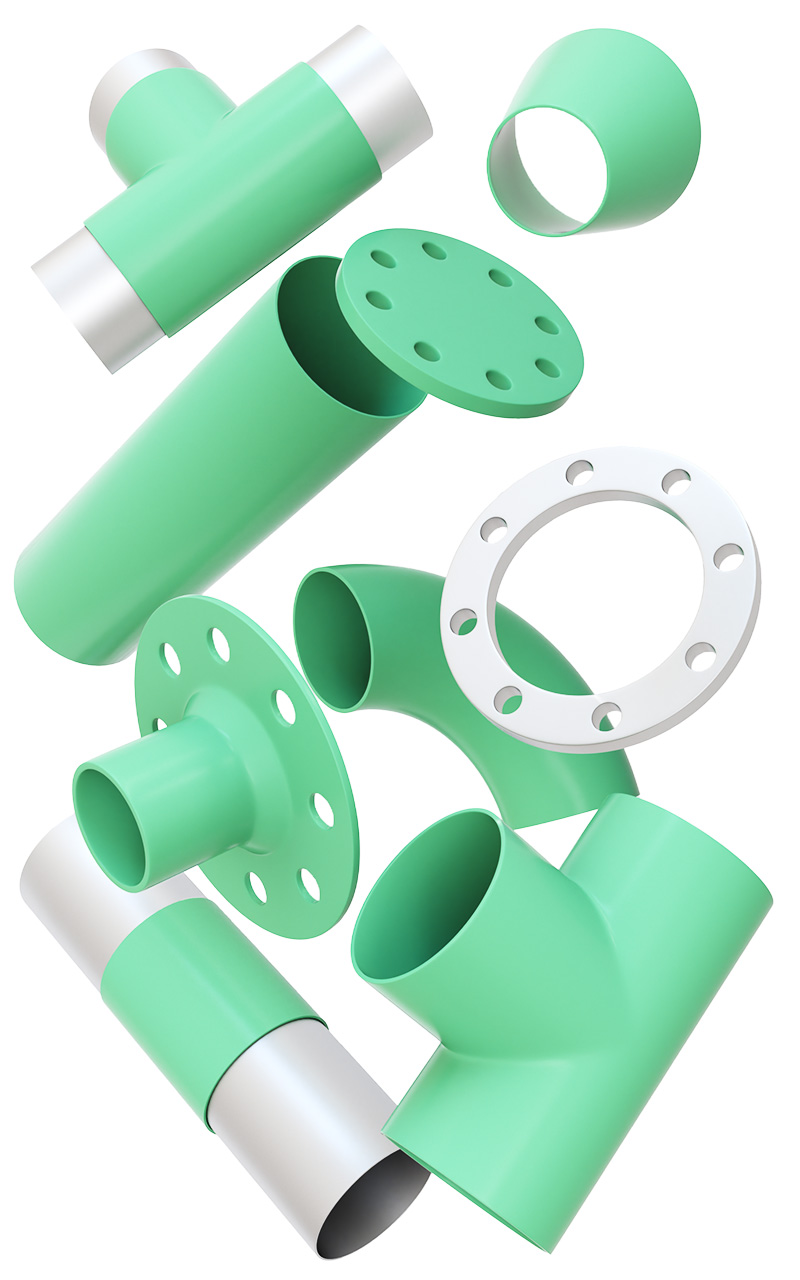

FiberFlo elements

Most Popular FiberFlo systems

Pipes

Based on polyester, vinylester or epoxy resin, reinforced with glass fiber, based on DIN 16965-4, DIN 16965-5 standard

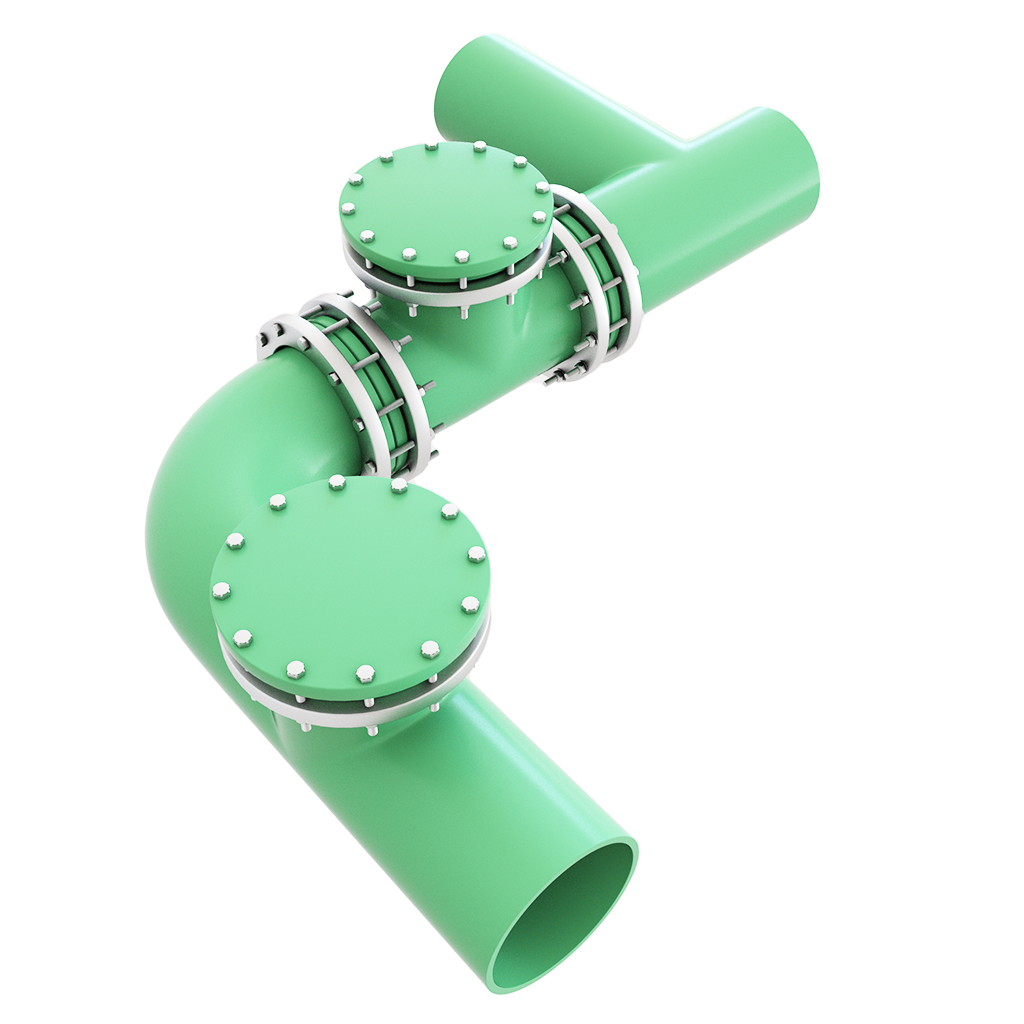

Elbows

30°, 45°, 90°

Based on polyester or vinylester resin, reinforced with glass fiber, based on DIN 16966-2 standard

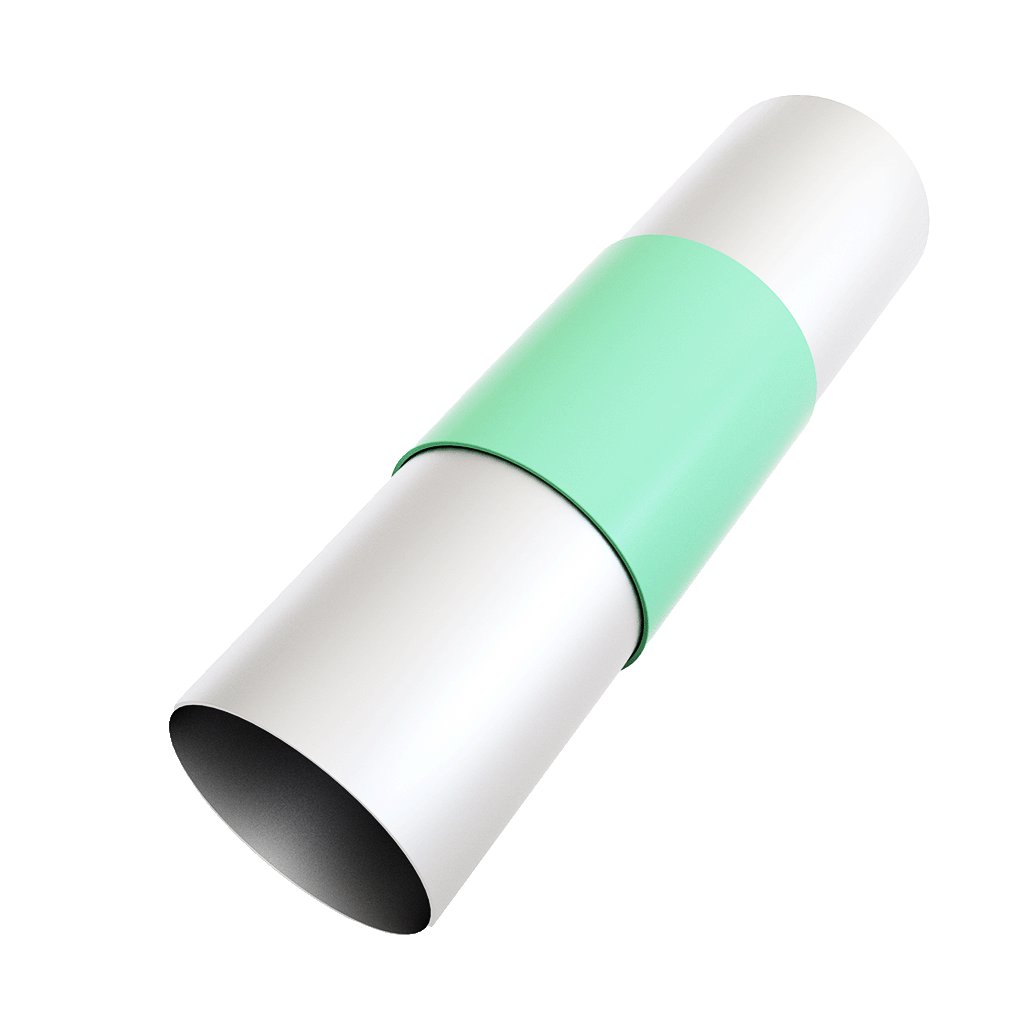

Butt joint laminate

Based on polyester or vinylester resin, reinforced with glass fiber, based on DIN 16966-8 standard

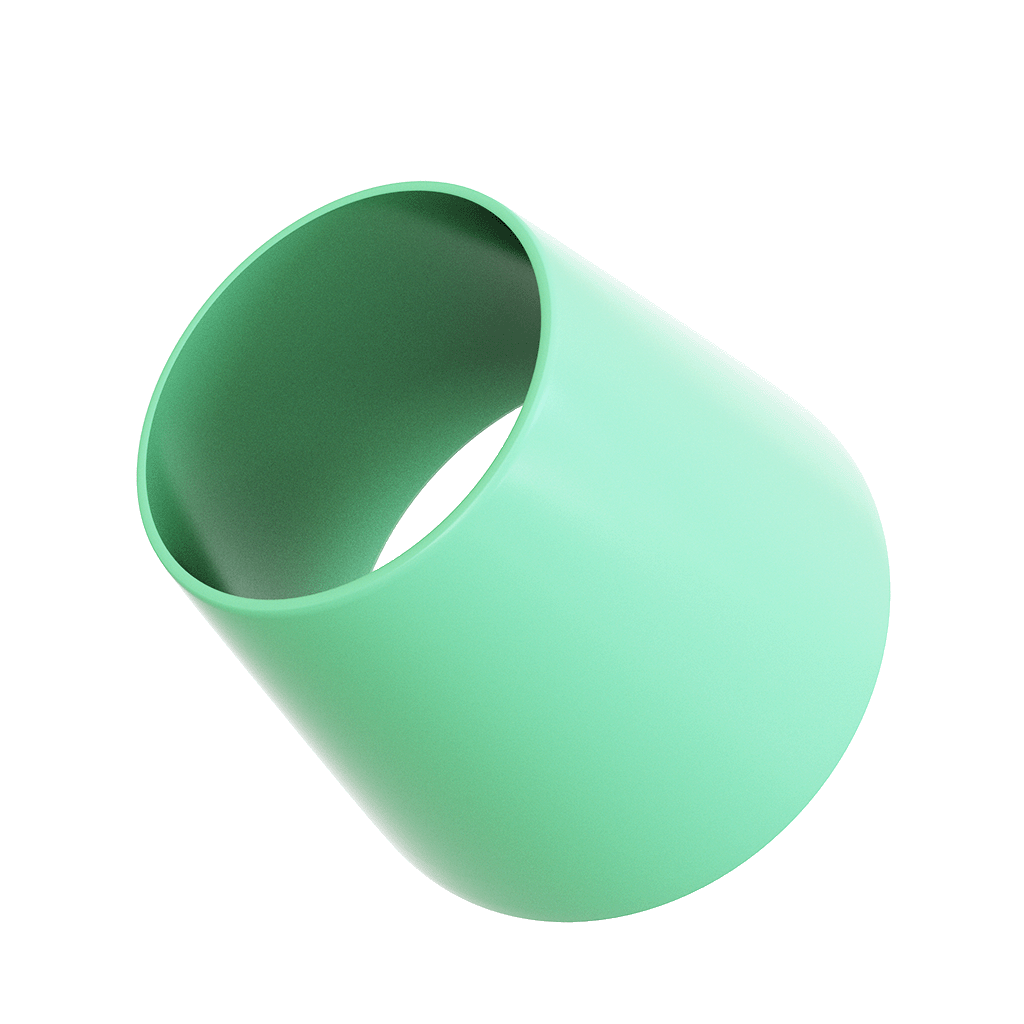

Reducers

Produced based on polyester or vinylester resin, reinforced with glass fiber, based on DIN 16966-5 standard

T- joints

Produced based on polyester or vinylester resin, reinforced with glass fiber, based on DIN 16966-4 standard

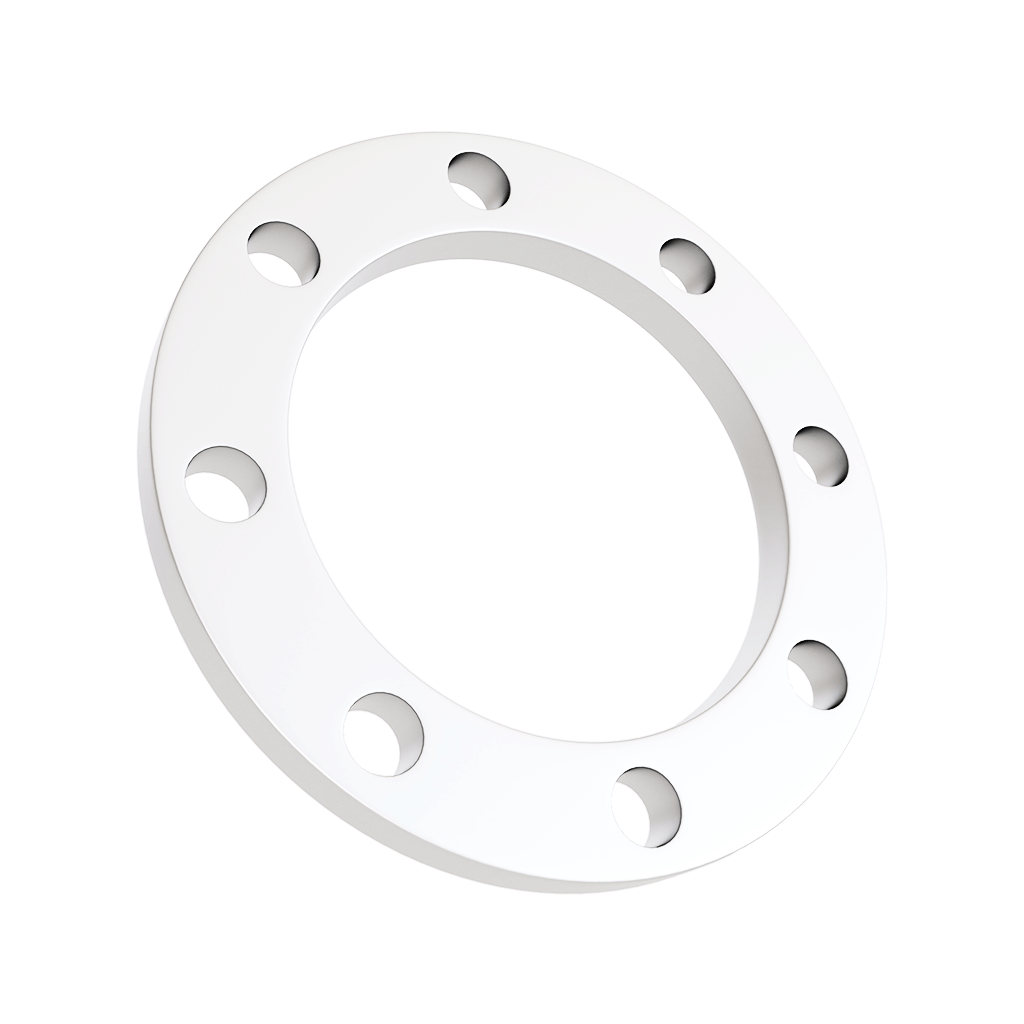

Flanges

Zinc plated or galvanized steel, stainless steel; drilling based based on PN-EN 1092-1 standard

Plugs

Based on polyester or vinyloester resin, reinforced with glass fiber, based on DIN 16966 standard; zinc plated or galvanized steel, stainless steel drilling based on PN-EN 1092-1 standard

Stub flanges

Produced based on polyester or vinylester resin, reinforced with glass fiber. Loose type (LF) based on DIN 16966-6 (B2) standard and fixed type (FF - V3) based on DIN 16966-6 standard, drilling based on PN-EN 1092-1 standard

FiberFlo systems

Application

Water, salt solutions, sewage, non-agressive gases

Description

According to DIN 16965-1 and DIN 16965-4 norm type A – system of laminates with 1mm of chemical resistant layer and constructional layer – cross-woven rowing with 60±5% glass fiber and 40±5% resin content

Application

Resistant to almost every single chemical substance except concentrated oxidized acids and chlorofenols

Description

Type D is a system according to DIN 16965-4 with a chemically resistant layer of min. 2.5mm with glass content 25±5%, resin content 75±5%. Structural layer for pipes: glass content 60±5%, resin content 40±5%. Structural layer for fittings: glass content 35-55%, resin content 45-65%

Application

Slimes, for example: gypsum suspension, water with sand and pneumatic transport, flue gas desulphurisation

Description

Constructed just like fiberflow system D. Additionally 30% of the resin mix contains silicone carbide (SiC), for additional abrasive protection

Application

Resistant to almost every single chemical substance except concentrated oxidized acids and chlorofenols. Usually used for agressive chemicals such as chlorine, ozone and liquids saturated with those gases

Description

System according to DIN 16965-5 with a chemical-resistant layer of min. 2.5mm with glass content 30±5%, resin content 70±5%. Structural layer: up to a thickness of 6.5mm made exclusively with glass mats, glass content 35-55%, resin content 45-65%